My criteria for a GPS watch is pretty simple. I need it to track distance and speed. I like it to have a way to download GPS track off the watch so I can manually upload it to Runkeeper (in this way to keep my record all in one place). And I like to achieve that with the lowest option as possible.

Most of the GPS watches are pretty expensive. There are only a handful of low cost GPS watch in the market in the range of around $100. While I am doing my research, a review by a guy who called himself DC Rainmaker caught my attention. The watch in review is Timex Marathon. Timex Marathon is one of the cheapest watch in the market, but interestingly is the first one that is made water proof. What is interesting about this watch is that even though it does not come with data download in the package, the reviewer has connected a data cable from Soleus (another low cost GPS watch maker) to Timex Marathon and the data download did work through it. What is more fun than having an easy hack to get the feature I wanted and at the same time save money!

So I promptly ordered a (used) Timex Marathon from a seller on Amazon at $50. It comes with a two-prone cable. I opened the back. Sure enough, there are four contacts made on the PCB board. That seems to be a perfect match to the four USB wire pin-outs. Out comes my soldering iron. Twenty minutes later, the cable is mod, and I have it connected to my computer. But ... my computer did not recognize the USB device! Back to the review page with more reading, and I started to read the comments. It turns out that I am not the first guy who tried the cheap mod. And it appears that it did not work that way.

A bit search of the installation directories of Soleus software found that it has a device driver folder for USBXpress. This is for Silicon Labs' USB serial chip. Could it be that it uses a serial port to talk to the watch? This makes sense as it is not necessary to put USB circuitry in the watch if it does not always need it. But a few attempts seems to indicate that the Soleus software is looking for some specific devices rather than a common serial port.

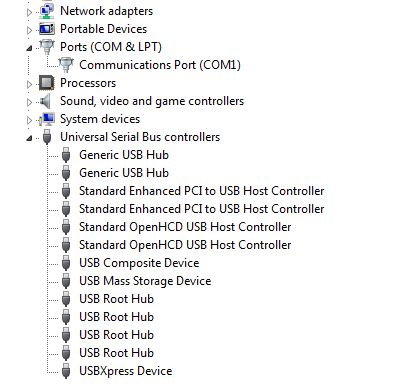

The proper four-prone cable is needed. After a few tries, I went ahead and ordered the data cable from Soleus for $29. It came in in a few days and when connect it up, the data download works. The cable itself is not just a simple cable, but has a Silicon Labs CP2012 chip inside. When connected to the computer, it appears as "USBXpress Device" instead of a serial port. Below is how it looks like in my device manager.

After much ado, I was able to do what I wanted with $80. The next working solution will cost $50 more. Soleus Fit watch costs $100, but needs additional $30 for the download cable. Soleus GPS 2.0 (which is identical to Timex Marathon, and is now water proof), has a $150 MSRP but is on sale at $130. This is not as good a saving as I originally anticipated, but it is not too bad. And I got some fun trying these.